Customer's problems:

- lack of supervision over the parameters of container power supply

- lack of information about power supply interruptions

- lack of possibility to provide the goods receiver with a documentation of proper and continuous power supply to the container

- necessity to pay contractual penalties (often unjustified) due to the deterioration of the goods.

Solution:

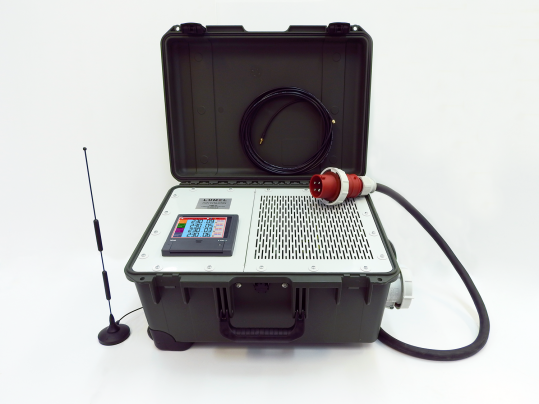

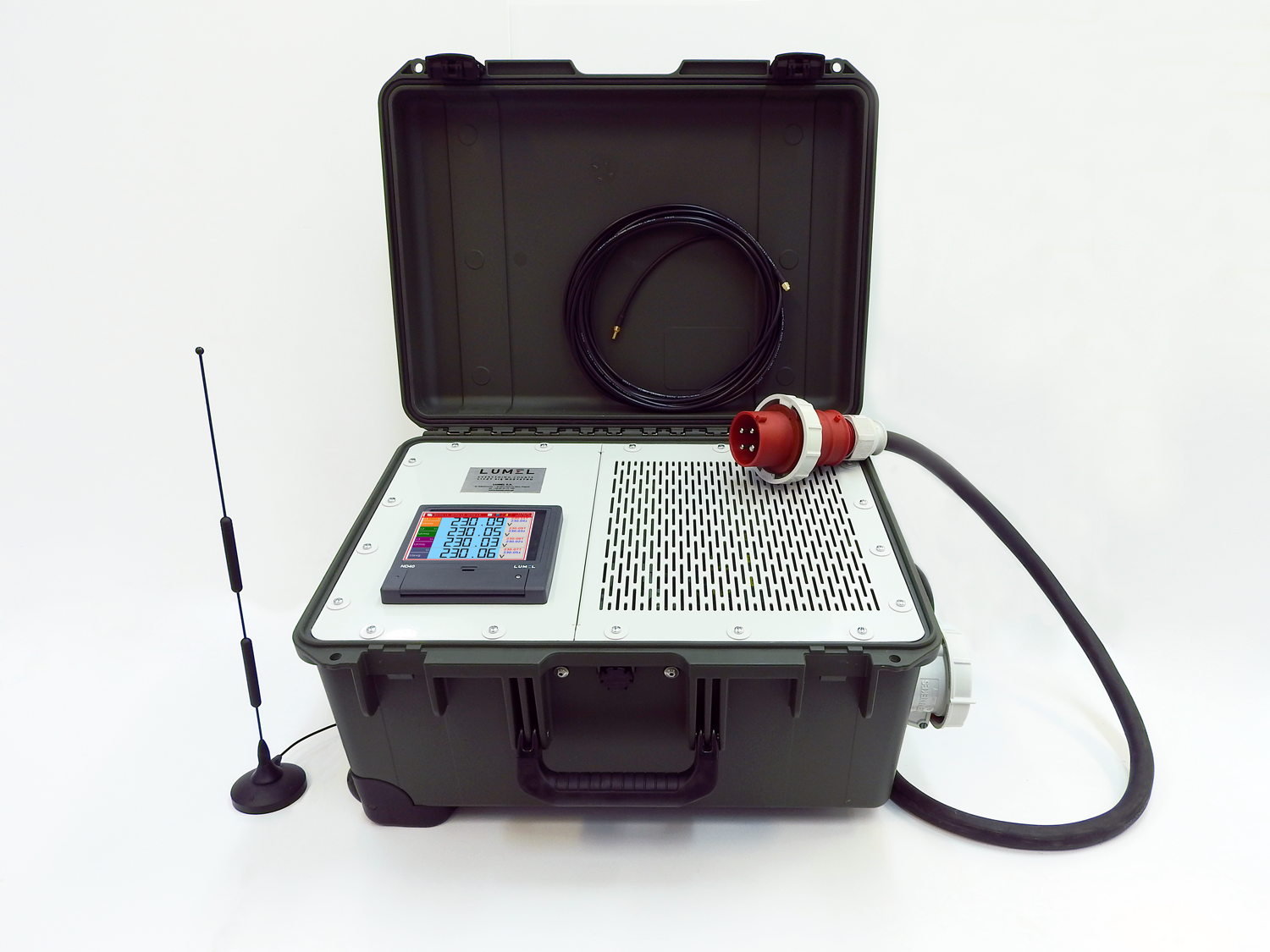

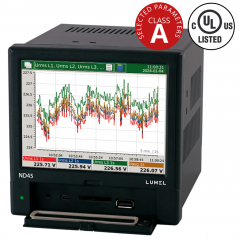

A special mobile measuring case was developed for the container which is made of materials ensuring water and dust protection as well as low weight. A complete measuring circuit consisting of the ND40 analyser, current transformers and necessary protection devices. Built-in Wi-Fi and/or GSM modules guarantee wireless communication, providing remote access to the current and archived measurement results 24/7.

Benefits after implementation of the solution:

- full control over the parameters of the container power supply - at any time the administrator can connect to devices via Wi-Fi or GSM networks

- immediate text message in case of any problems with the container power supply

- recording of power supply parameters with a division into individual container numbers - it is possible, at any time, to provide the goods receiver with the power supply parameters of "their" reefer

- elimination of contractual penalties for possible goods “perishing”